PAD196 – Rev C

KEY FEATURES

- LOW COST

- SMALL SIZE – 50mm SQUARE

- HIGH VOLTAGE – 2050 VOLTS

- OUTPUT CURRENT– 50mA

- 12 WATT DISSIPATION CAPABILITY

- 5V/µS SLEW RATE

APPLICATIONS

- HIGH VOLTAGE INSTRUMENTATION

- PIEZO TRANSDUCER DRIVE

- ELECTRON BEAM FOCUSING

DESCRIPTION

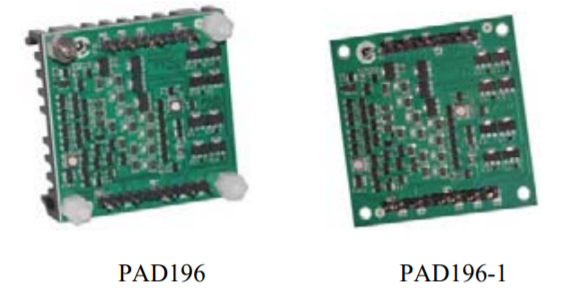

The PAD196 high voltage operational amplifier is constructed with surface mount components to provide a cost effective solution for many industrial applications such as high voltage instrumentation. With a footprint only 50mm square the PAD196 offers outstanding performance that rivals more expensive hybrid components. Integrated passive heat sink cooling is included. User selectable external compensation tailors the amplifier’s response to the application requirements. A single resistor programs the current limit feature. The PAD196 is built on a thermally conductive but electrically insulating substrate. No BeO is used in the PAD196. For custom applications the PAD196-1 version of the amplifier is available without the integrated heat sink. The circuit is conformal coated for additional safety and reliability. See “CONFORMAL COATING” paragraph on page 5.

A NEW CONCEPT

A critical task in any power amplifier application is cooling the amplifier. Until now component amplifier manufacturers often treated this task as an after-thought, left for the user to figure out. At Power Amp Design the best heat sink is chosen at the start and becomes an integral part of the overall amplifier design. The result is the most compact and volumetric efficient design combination at the lowest cost. In addition, this integrated solution concept offers an achievable real-world power dissipation rating, not the ideal rating usually cited when the amplifier case is somehow kept at 25℃. The user no longer needs to specify, procure or assemble separate components.

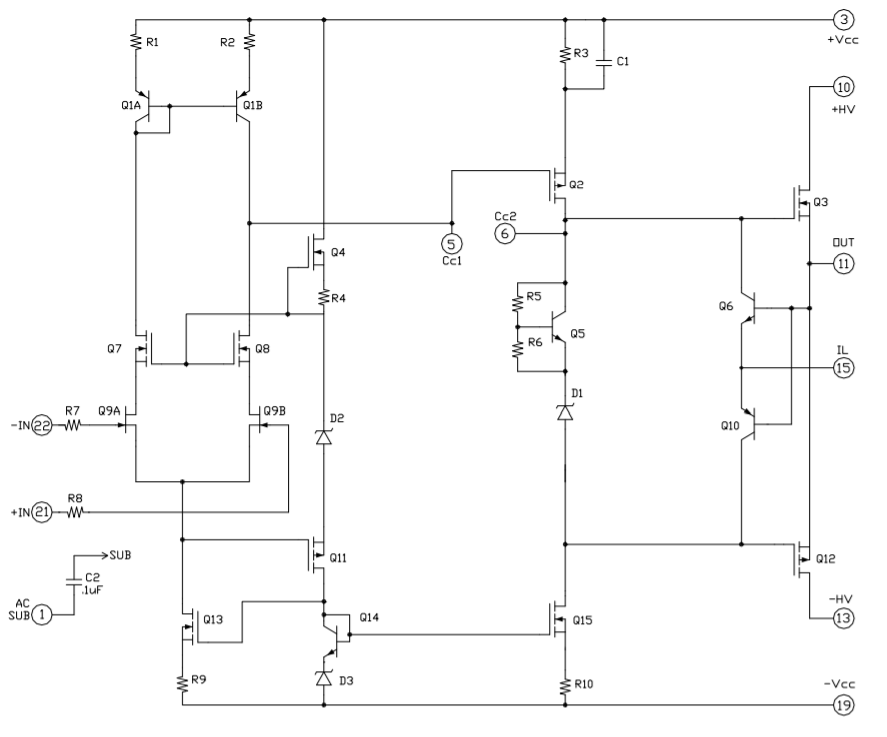

CIRCUIT & CONNECTIONS

EQUIVALENT CIRCUIT

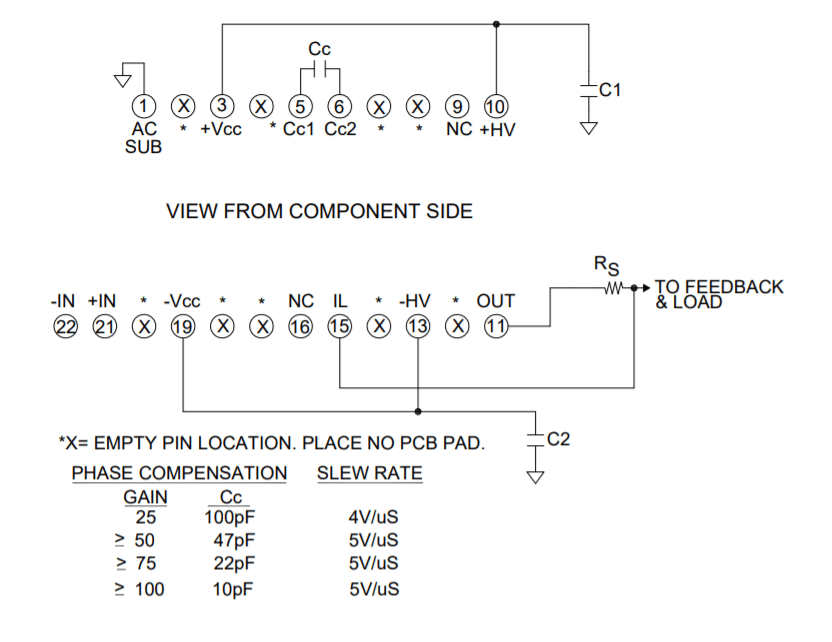

PINOUT & CONNECTIONS

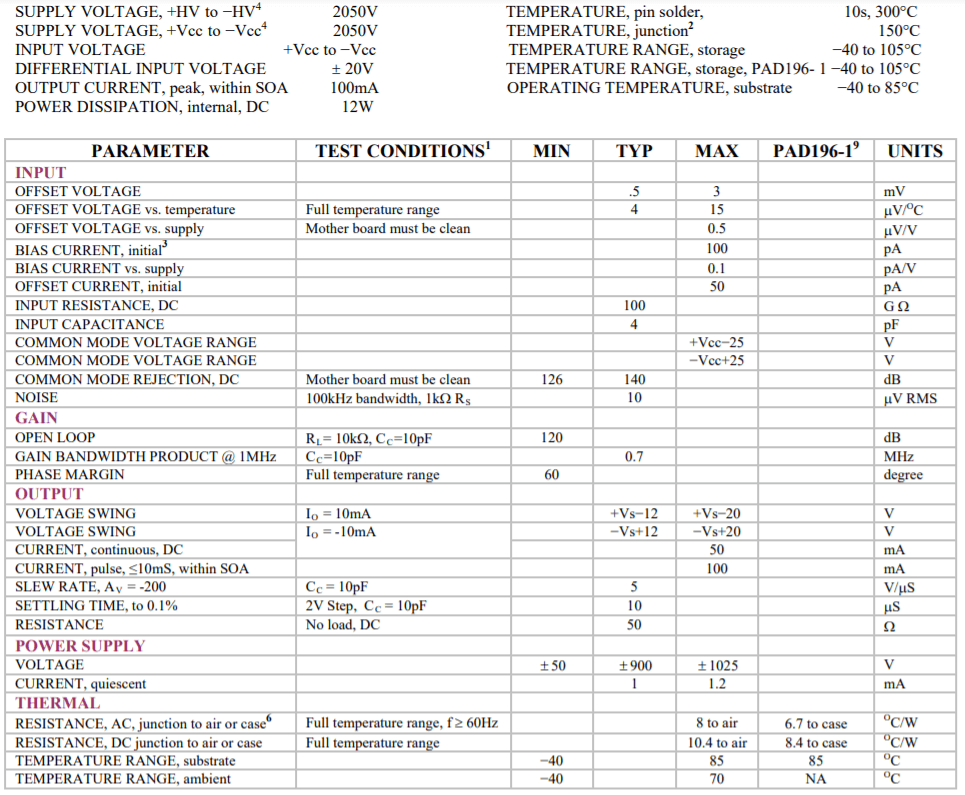

ABSOLUTE MAXIMUM RATINGS SPECIFICATIONS

NOTES:

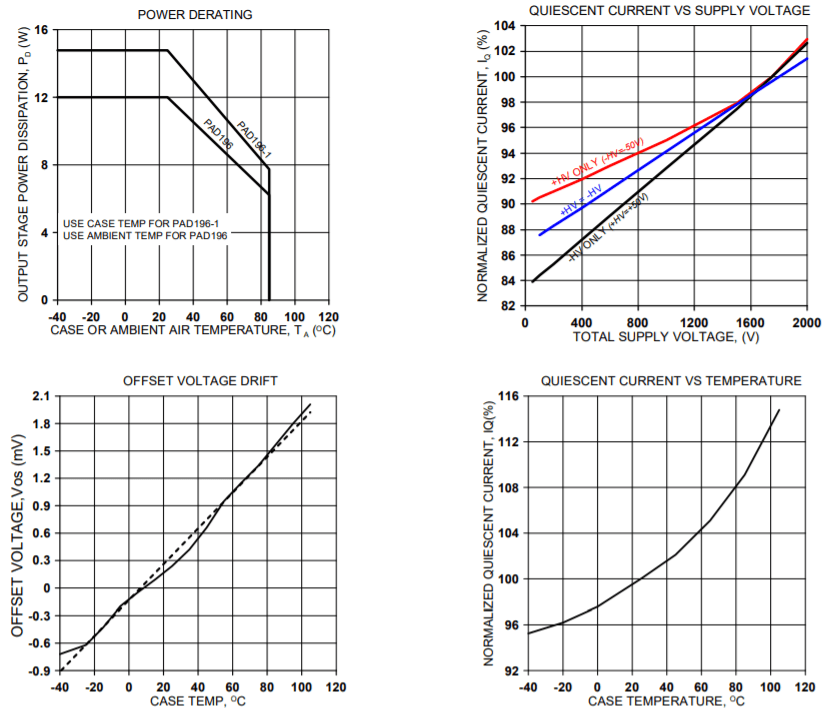

- Unless otherwise noted: TC = 25℃, compensation Cc = 150pF, DC input specifications are ± value given, power supply voltage is typical rating.

- Derate internal power dissipation to achieve high MTBF.

- Doubles for every 10OC of case temperature increase.

- +HV and −HV denote the positive and negative supply voltages to the output stage. +Vcc and –Vcc denote the positive and negative supply voltages to

the small signal stages. +Vcc and –Vcc may not be more than + and – 20V greater than +Vs and –Vs respectively. - Rating applies if the output current alternates between both output sets of transistors at a rate faster than 60Hz.

- Power supply voltages +Vcc and −Vcc must not be less than +HV and −HV respectively. Total voltage +Vcc to −Vcc 2050V maximum.

- Specifications for the PAD196-1 are the same as for the PAD196 except as shown in this column.

OPERATING CONSIDERATIONS

SAFETY FIRST

The operating voltages of the PAD196 are potentially deadly. When developing an application circuit it is wise to begin with power supply voltages as low as possible while checking for circuit functionality. Increase supply voltages slowly as confidence in the application circuit increases. Always use a “hands-off” method whereby test equipment probes are attached only when power is off. Be sure test equipment and probes can withstand 2000V.

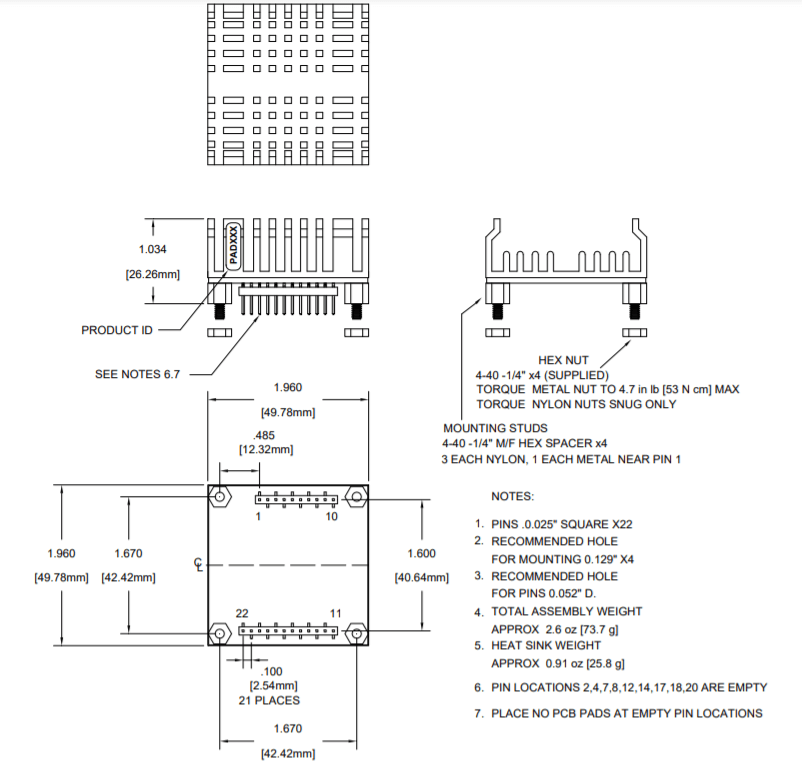

MOUNTING THE PAD196 AMPLIFIER

The amplifier is supplied with four 4-40 M/F hex spacers at the four corners of the amplifier. The hex spacer near pin 1 is metal and the other three hex spacers are nylon for extra safety and arc resistance. Once the amplifier is seated, secure the module with the provided 4-40 nuts and torque the metal nut to 4.7 in lb [53 N cm] max. Tighten the nylon nuts snug only. See “Dimensional Information” for a detailed drawing. It is recommended that the heat sink be grounded to the system ground. This can easily be done by providing a grounded circuit board pad around the hole near pin 1 for the metal mounting stud. The other 3 mounting spacers are nylon and do not conduct.

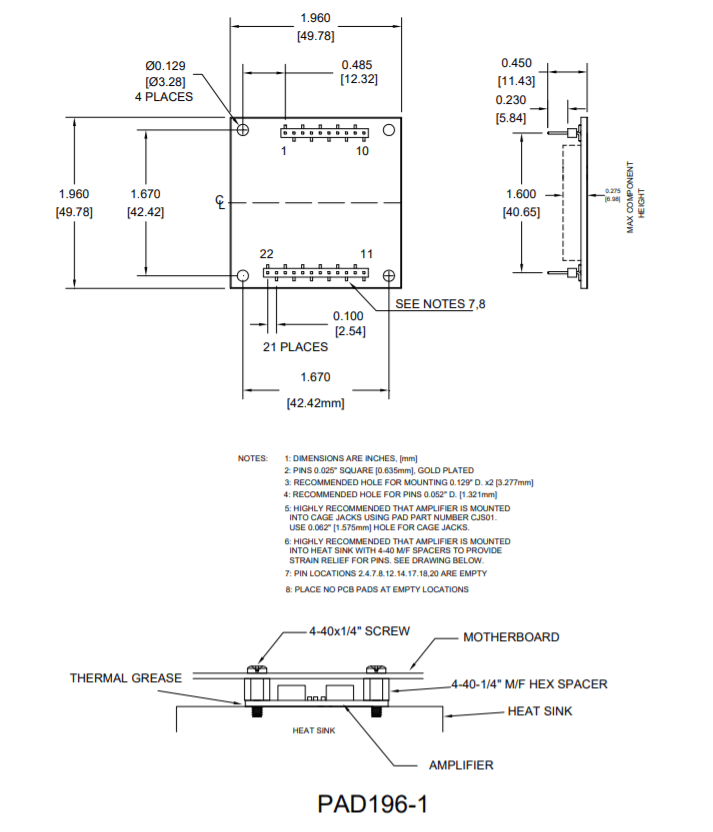

MOUNTING THE PAD196-1 AMPLIFIER

In many applications the amplifier must be attached to a heat sink. Spread a thin and even coat of heat sink grease across the back of the PAD196-1 and also the heat sink where the amplifier is to be mounted. While holding on to the lead frames push the amplifier into the heat sink grease on the heat sink while slightly twisting the amplifier back and forth a few times to bed the amplifier into the heat sink grease. On the final twist align the mounting holes of the amplifier with the mounting holes in the heat sink. Be careful not to disturb the soft silicone overcoat on the amplifier’s components. Finish the mounting using a metal 1/4″, 4-40 hex male-female spacers at the location near pin 1 and torque to 4.7 in oz [3.8 N cm] max. At the other three locations use 1/4″ nylon hex male-female spacers and nylon hex nuts. See Dimensional Information for additional recommendations.

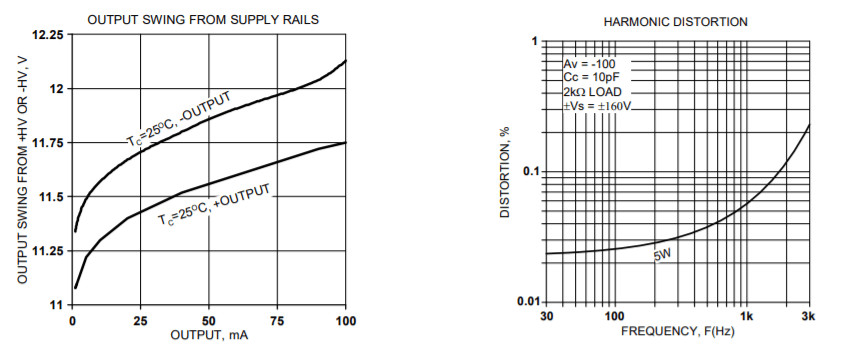

PHASE COMPENSATION

The PAD196 must be phase compensated. The compensation capacitor, CC, is connected between pins 5 and 6. The compensation capacitor must be an NPO type capacitor rated for 500-1000V. On page 2, under Amplifier Pinout and Connections, you will find a table that gives recommended compensation capacitance value for various circuit gains and the resulting slew rate for each capacitor value. Consult also the small signal response and phase response plots for the selected compensation value in the Typical Performance Graphs section. A compensation capacitor less than 10pF is not recommended.

EXTERNAL CIRCUIT COMPONENTS

The output of the PAD196 can swing up to +/- 1000V (or 2000V unipolar) and this may stress or destroy external components that are often not seriously considered when developing circuits with small signal op amps. For example, it is often overlooked that the usual voltage rating for metal film resistors is only 200V and that application circuits using the PAD196 may place up to 2000V across the feedback resistor. High voltage rated resistors may be purchased for the feedback circuit or, alternately, several ordinary resistors may be placed in series to obtain the proper voltage rating. We recommend at least 10 resistors in series for the feedback resistor. The compensation capacitor CC is a NPO type and is rated for 500-1000V. The voltage rating of the connecting wire and PCB spacing between pads and connecting traces needs to be considered as well. See application note AN-16 for details.

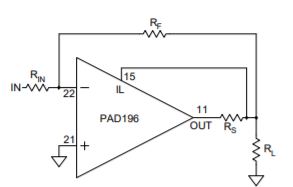

CURRENT LIMIT

Current limit can be programmed by attaching a suitable value resistor as shown in Figure 1. The value of the limited current can be approximately calculated by:

IL=.65/RS

Where IL is the value of the limited current and RS is the value of the current sense resistor. It is important that the type of resistor chosen for RS be non-inductive. A wirewound resistor is not a good choice even if it rated as “noninductive” since it will exhibit significant inductance at some frequency. A better choice is a type of resistor that is more inherently non-inductive such as a metal film resistor or a thick film resistor. The power dissipation rating of the sense resistor should not to be forgotten. The current limit circuitry works by diverting the stage currents of the amplifier into the output circuit (about 5mA) and this introduces an error term compared to the approximate equation given above. As the current limit value is reduced the proportion of the error term increases. The practical range of current limit is from 50mA to 2mA. The current limit decreases 2.2mV/℃ with increasing temperature since the sense voltage for calculating the current limit is the emitter-base circuit of a bipolar transistor.

Current Limit

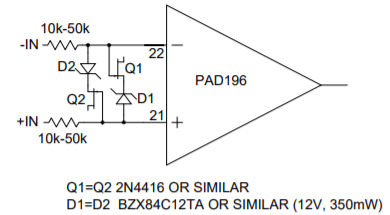

INPUT PROTECTION

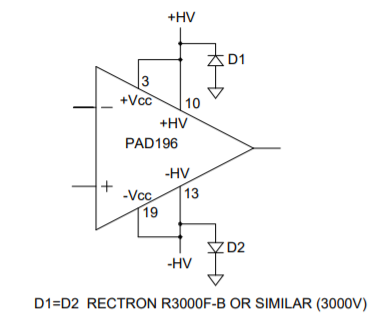

In applications where the input differential voltage may be exceeded (dc or transient) it is important to add differential input voltage protection. See Figure 2.

Input differential voltage protection

It is important that the power supply connections to the PAD196 not be open. If for example, the negative supply connection were to open the internal circuitry of the amplifier will bootstrap the amplifier to the positive supply through the feedback gain-setting resistor. When the +IN is grounded the input circuit is clamped to ground while the output of the amplifier will float to the positive supply voltage via the bootstrapping effect. The input differential voltage of the amplifier will be exceeded destroying the input stage. This is one good reason to protect the input as shown in Figure 2. But it is also a good reason to clamp the power supply pins as shown in Figure 3 below.

Power supply clamps

TYPICAL PERFORMANCE GRAPHS

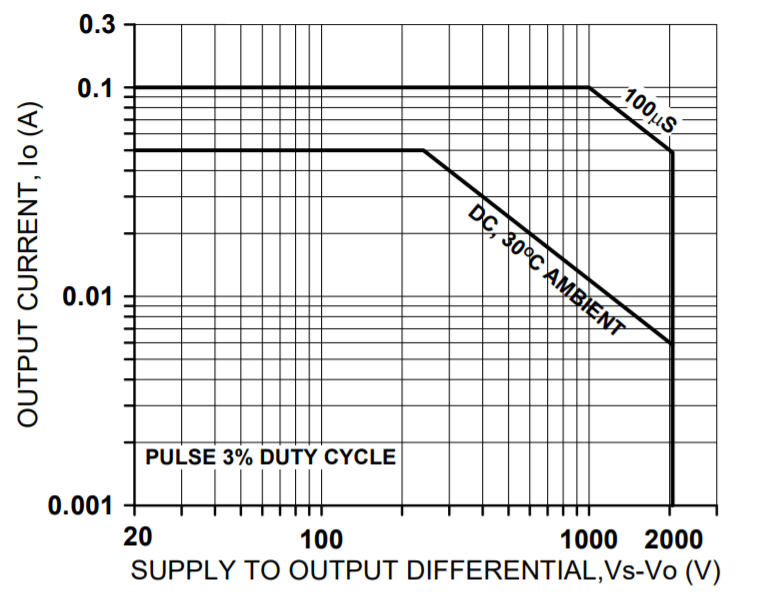

SAFE OPERATING AREA

DIMENSIONAL INFORMATION