Downloads

Datasheet

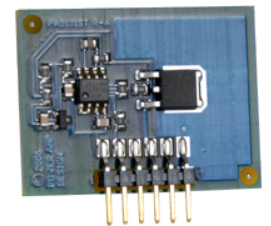

PAD131 Rev – D

KEY FEATURES

- LOW COST ACCESSORY

- REDUCES AUDIBLE FAN NOISE

- INCREASES FAN LIFE

- CONVENIENT SIP PIN-OUT

- OPERATES FROM 12-15 VOLTS

APPLICATIONS

- HIGH POWER AMPLIFIER ADD-ON

- REDUCED POWER APPLICATIONS

- AUDIBLE NOISE SENSITIVE APPLICATIONS

DESCRIPTION

The PAD131 fan controller module works with all power op amps offered by Power Amp Design and may be added to the application circuit at any time. The module was designed to extend fan life and reduce audible fan noise for those power amplifier applications where maximum cooling is not required. The PAD131 monitors the substrate temperature output of the host power amplifier and adjusts its cooling fan rpm to keep the heat sink temperature to 65°C or less where possible. Many power amplifier applications either do not require maximum cooling or the application makes intermittent high power demands. When the temperature rises above 65°C the module drives the cooling fan at maximum RPM for maximum cooling and throttles back the rpm as the temperature falls. The number one failure mechanism in fans is bearing wear. Lower fan rpm translates into less wear on the bearings and less audible noise.

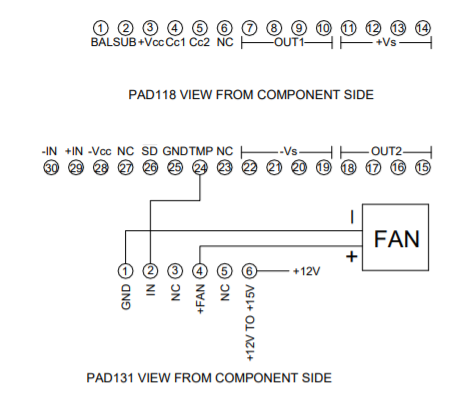

CIRCUIT & CONNECTIONS

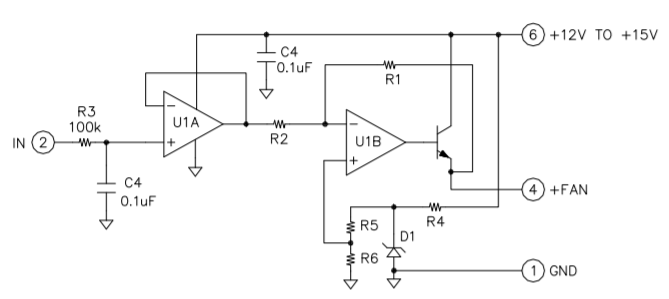

EQUIVALENT CIRCUIT

PAD131 TYPICAL CONNECTION TO HOST AMPLIFIER

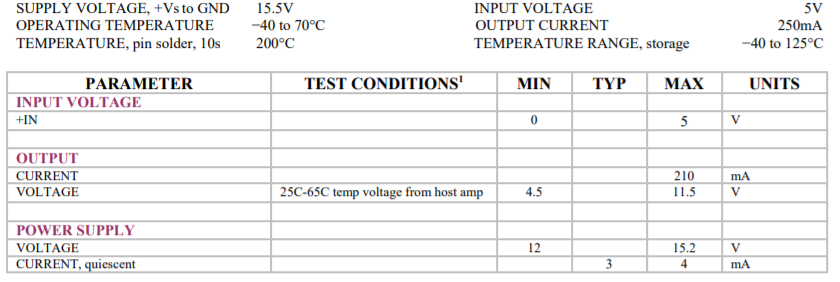

ABSOLUTE MAXIMUM RATINGS

OPERATING CONSIDERATIONS

FAN CONTROLLER FUNCTION

Not all power amplifier applications require maximum cooling of the amplifier. An amplifier capable of dissipating 100W, for example, might not be required to dissipate more than 50W or even less in its application circuit. Yet, in either case the cooling fan will be operating at maximum rpm. Maximum fan rpm will keep the amplifier at the lowest operating temperature, but this may not be necessary even when considering amplifier reliability.

Overall reliability also must consider the cooling fan. The leading cause of fan failures is bearing wear. Even though the L10 rating of the fans supplied with all of our amplifiers is 45k hours some applications may benefit from an even longer life.

The PAD131 monitors the analog output (TMP) of host amplifier and adjusts the rpm of the fan accordingly. As the substrate temperature of the host amplifier rises, the rpm of cooling fan increases and decreases the operating temperature of the host amplifier. As the operating temperature of the host amplifier rises to 65C, the PAD131 will increase the rpm of the cooling fan from minimum (perhaps off) to maximum. When the operating temperature of the host amplifier reaches 65C or above maximum cooling is applied to the amplifier. Any operating condition that allows the amplifier to operate at a temperature lower than 65C can benefit from the PAD131 Fan Controller Module. At lower operating temperatures the rpm of the fan decreases thus extending its life by reducing bearing wear. At the same time, lower fan rpm results in less audible fan noise.

Applications that require less than maximum cooling such as applications where higher power dissipation in the amplifier is intermittent will benefit the most.

The operating temperature of the host amplifier can be predicted using the PAD Power Excel based design spreadsheet available on the Power Amp Design web site.

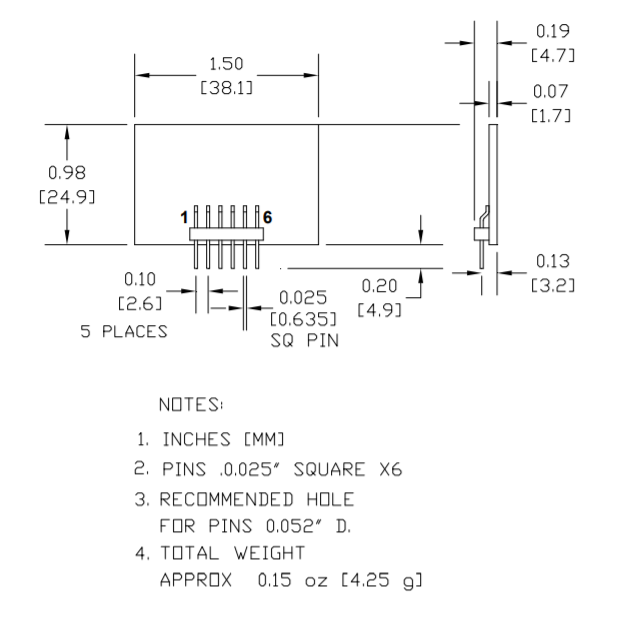

DIMENSIONAL INFORMATION